The automotive industry has always relied on innovative technologies to improve processes and optimize the quality of production for motors. In recent years, use cases of augmented reality (AR) have been cropping up at an increasing pace, highlighting the value of the technology to the industry.

The evolutionary change that AR is capable of bringing the industry can impact every stage of a car’s path from the production line to the driveway of a new owner.

In utilizing augmented reality, it’s possible to not only design more efficient cars but to also assist prospective buyers and help maintain motors, helping to promote better safety in vehicles.

Let’s take a deeper look at some of the leading examples of the transformative change that AR is capable of providing the automotive industry:

Optimizing Automotive Design

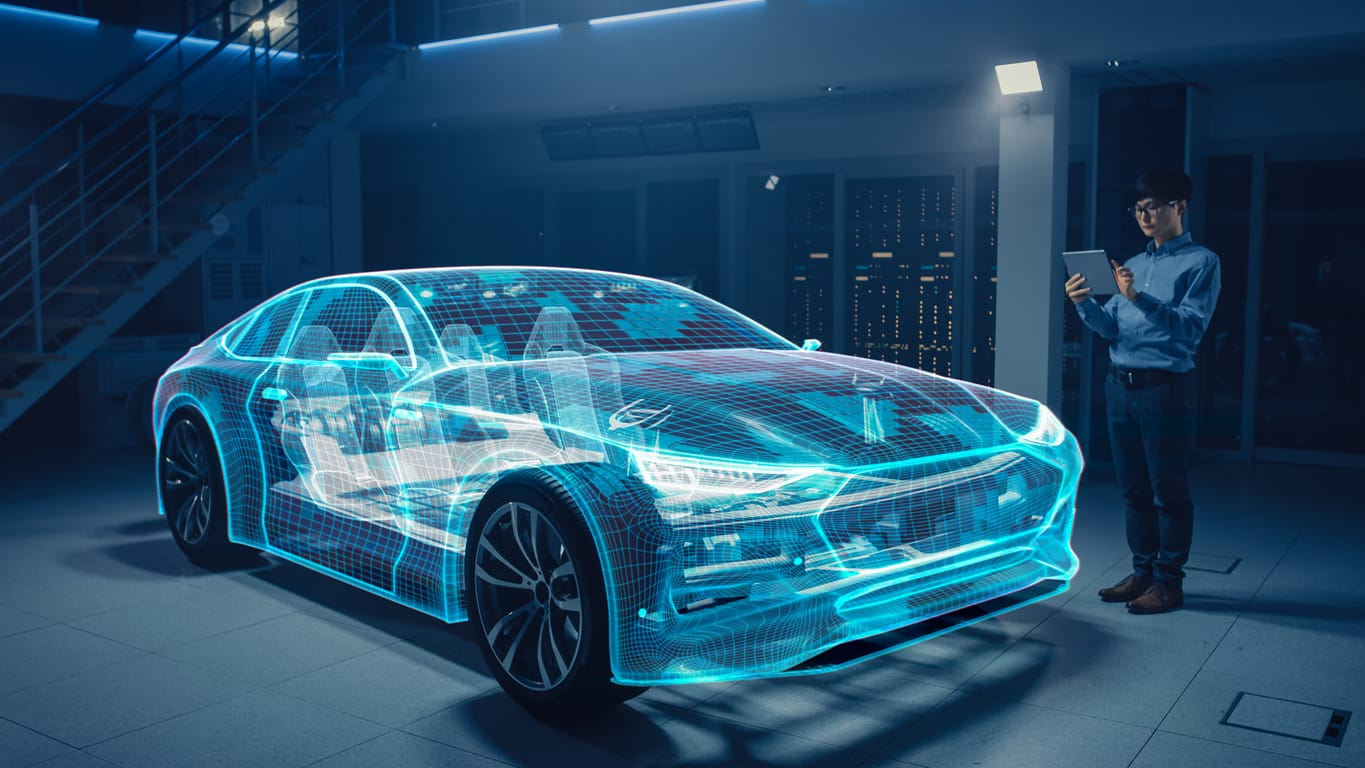

Augmented reality has the potential to revolutionize automotive design. Through the power of AR, it’s possible for designers to craft richly detailed virtual models of vehicles and make essential adjustments in real time.

This process enables quick and seamless modifications that can help save time and money. Not only can these models provide a fully functional overview of a vehicle during the design process, but it can also pave the way for more immersive prototyping of cars to better uphold safety standards.

We’re already seeing augmented reality prototyping enter the automotive landscape to improve the design of vehicles. For instance, in 2019, Ford became the first vehicle manufacturer to utilize Gravity Sketch, which is a 3D tool utilizing reality technology to help the company’s designers to craft more human-centric vehicle designs.

Delivering Assembly Line Efficiency

Because AR has the ability to join forces with smart glasses to offer hands-free access to data in real-time, car manufacturing employees have the ability to gather masses of information without having to individually test component parts or take any extra steps.

This can help to improve workplace safety while also paving the way for intelligent 3D visualizations that can help not only improve diagnostics but can also be used to improve the quality of training delivered to warehouse employees.

According to a recent study at the University of Maryland, subjects saw a recall improvement by as much as 8.8% when using a virtual learning environment. This can help to bring vast improvements to assembly line efficiency in comparison to more traditional training approaches.

Augmented reality can even provide more step-by-step instructions during the manufacturing process for staff, while Key Performance Indicators (KPIs) can help firms to quickly identify skill gaps that can be quickly addressed among employees.

Changing the Game in Car Retail

We may also see augmented reality transform the car purchasing experience in a new car industry that’s in need of a boost.

Although new car registrations soared 18% in 2023 in comparison to the year prior, it’s believed that much of these sales were driven by fleets, as opposed to consumers who are becoming more wary of how they spend their money.

However, AR could help to make the car purchasing process altogether more seamless by helping prospective buyers get up to grips with the models they’re most interested in.

Imagine being able to position a full-scale 3D rendering of a car on your driveway, and to physically explore the vehicle by walking around the digital structure and looking inside.

Virtual car tours are becoming more commonplace among car dealerships around the world, where AR experiences help buyers to get to grips with motors while shopping online.

Jaguar Land Rover has also utilized a similar technology to allow customers to test drive its Velar vehicle. These 360-degree experiences of the car’s interior take place when a user clicks on a banner ad, and different areas of their screen can reveal more about certain in-car features.

The Next Generation of Car Maintenance

Augmented reality can also improve the longevity of a vehicle through better-assisted maintenance programs for drivers.

If you’re unfamiliar with mechanics, it’s possible to undertake maintenance tasks through a fully immersive and engaging AR tutorial. Whether you’re uncertain of how to change your windscreen wiper fluid or need to top up your engine oil, augmented reality can help you to perform these tasks confidently and efficiently.

In the future, we may even see augmented reality become more adept at highlighting these problems before they become costly repair work. For instance, it may be able to use onboard data to pinpoint a windshield crack and its rate of growth, helping to alert the owner to find an auto glass shop service in time before it gets worse.

The beauty of augmented reality is that it’s already busy improving the automotive industry for all players, from manufacturers to car owners. In offering more intuitive prototyping, manufacturing, and purchasing procedure, the benefits of AR can help to make the world of motoring more efficient, from the production line to the driveway.

With the technology still emerging it seems that AR in the automotive industry has plenty more miles in the tank.

The post From Production Line to the Driveway: How Augmented Reality is Reinventing the Car appeared first on Datafloq.